Boxin Electronics is a professional multi-category headset OEM / ODM manufacturer,

providing customized manufacturing services for UC headsets, education headsets, ANC headphones, gaming headsets, and DJ headphones.

We focus on product reliability, real-world application performance, and the ability to mass-produce products.

We don’t do one-off OEM manufacturing; we focus on long-term, stable mass production.

Business communication & unified communications

Classroom, e-learning, and school devices

Active noise cancellation consumer headphones

Gaming, streaming, and voice communication

Monitoring, studio, and professional audio use

Each category is supported with dedicated engineering considerations based on its application.

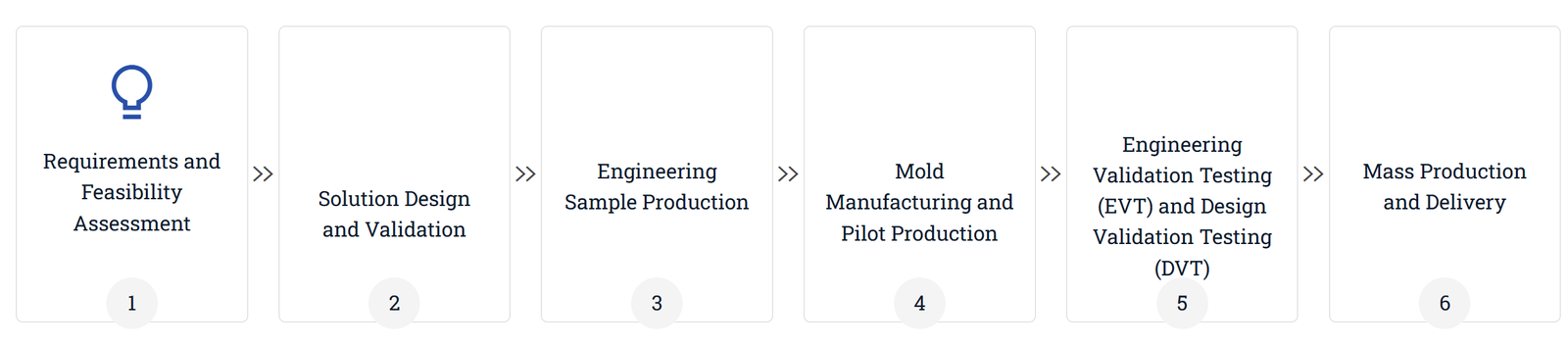

We will begin by gaining a thorough understanding of your product concept and working with you to establish clear success criteria.

Key customization aspects include:

1. Core Functionality Customization: Active Noise Cancellation (ANC) or Passive Noise Cancellation, Single or Dual Earbuds, Number of Microphones, USB/Bluetooth/QD Interface, Durability Requirements

2.Appearance Design: Color, Materials (Plastic, Metal, Leather), Logo Processing (Screen Printing, Laser Engraving, Hot Stamping)

3.Audio Tuning Preferences: Voice Clarity, Bass Enhancement, Equalization

4.Packaging and Accessories: Color Box Design (Size, Color, Dimensions), Carrying Bag, Spare Earpads, Extension Cable

Boxin Output:

◆ Preliminary Technical Feasibility Analysis

◆ Cost Estimation

◆Development Timeline Suggestions

Importance:

This step helps identify technical and cost risks early on, ensuring the project starts on a feasible and controllable basis.

|  |

Your ideas will be transformed into a clear and actionable technical blueprint.

Boxin’s main deliverables include:

3D renderings and CMF (Color, Material, Surface Finish) solutions

Confirmation of major chipset platforms (e.g., Qualcomm, Jerry)

Cavity structure and microphone pickup path design

Packaging design sketches and accessory list

Signing a confidentiality agreement with the client and confirming the solution.

Importance:

This stage ensures the client sees a clear design solution, avoiding subsequent rework.

|  |

Rapidly produce sample models to verify the core functionality and user experience of the product.

Sample production includes:

PCB design and PCBA assembly

CNC or 3D printing of mechanical parts

Acoustic tuning (frequency response, sensitivity, signal-to-noise ratio)

Functional testing (call quality, noise reduction, compatibility)

Surface finishing and logo processing

We typically provide 1-3 engineering samples, followed by 1-2 iterations of optimization based on your feedback.

Importance:

Engineering sample production is used for actual performance verification before entering the mold design stage.

|  |

After customer confirmation of the engineering samples, we will prepare for mass production.

This stage includes:

2D drawing and DFM (Design for Manufacturability) review

Injection mold and metal mold development

T0/T1 mold trial molding for dimensional, assembly, and appearance verification

Final mold approval and mold finalization

Mold delivery cycle is typically 4-6 weeks, with weekly progress updates.

Importance:

Ensuring consistent and controllable quality throughout mass production.

|  |

Engineering Validation Testing (EVT)

Small Batch Production (10-30 units)

Reliability Testing: Drop Test, High and Low Temperature Test, Insertion and Withdrawal Life Test, Aging Test

Functional and Performance Qualification

Design Validation Testing (DVT)

Pilot Production (200-500 units)

First Article Inspection (FAI) and Full-Line Validation

Submit Samples for Certification (CE, FCC, RoHS, etc.)

Final Engineering Change Confirmation and Mass Production Approval

Importance:

EVT and DVT can significantly reduce certification risks and quality issues before full-scale production.

|  |

After verification and approval, the project enters the stable mass production phase.

Our quality system includes:

Incoming Quality Control (IQC)

In-Process Quality Control (IPQC)

Outgoing Quality Control (OQC)

Acoustic and Microphone Performance Verification

Reliability and Aging Testing

All production is managed under an ISO-certified quality system to ensure batch-to-batch consistency.

|  |